SlimmeMolen specs for traditional wind mills

SlimmeMolen specs for traditional wind

mills by Victor Reijs

is licensed under CC

BY-NC-SA 4.0

Introduction

This gives an overview of what sensors for this mill project

(Internet of Things molen -> SlimmeMolen) are needed and what

the connectivity (power, Internet, cloud) is expected.

A project

of using CFD (Computational Fluid Dynamics) is running since

Janaury 2023 to determine the windmill biotope.

The project aims are:

- Determine which parameters (and thus sensors) are important to

determine/predict windmill biotope evaluation

- Prototype the

SmartMolen ideas

- Get experience with CFD for determining the windmill biotope

- Validate CFD with actual measurements at a few windmills

- Evaluate CFD and other windmill biotope rules (DHM-formula [De

Hollandsche Molen] and Stephen Temple Molenbiotope spreadsheet)

and possibly propose possible improvements.

- Which CFD services can be used

looking at pricing, user-friendliness, experience, etc.

- Provide a how-to-guide, workflow and training around windmill

biotope for windmillers

- Publish the findings in mill-related publications and

interested organisations

This web page looks mainly at bullet 1.Experience with a prototype

of SmartMolen is available

here.

Bullets 3 and 4 are covered in several separate pages for: Den Oord,

Zwiepse Molen

and Impington.

As part of the Impington and SlimmeMolen research, bullet 5 will

be incorporated (DHM-formula

and Steven

Temple Molenbiotope-spreadsheet).

Bullets 6, 7 and 8 will be picked up as soon as more confidence

has been gained with CFD and measurements (aka the earlier

bullets).

A project has started (since Oct. 2024) by DHM to verify CFD with

wind measurements at a Dutch mill (bullets 3, 4, 5, 6, 7 and 8).

Why measuring around a mill?

There are a few areas why one wants to measuring things around a

traditional wind mill:

- Education/tourism/management

- Security/maintenance

- Productivity

- Short term local weather prediction

- Mill biotope

Each of them has measurements that can support that area and will

provide for a reference database of how wind mills perform and

will allow the verification of modelling the mill's biotope.

Luckily these areas have some common measurements:

Measurements

|

Areas

|

|

Projects

|

Education

|

Security

/

Maintenance

|

Productivity

|

Short

term

local weather

prediction

|

Mill

biotope

|

Spinning mills

|

eMill

|

smartmolen

|

SlimmeMolen

|

Revolutions per minute

|

x

|

x

|

x

|

|

x

|

|

x

|

|

x

|

x**

|

Number of turns per day

and/or year

|

x

|

|

x

|

|

|

|

x

|

x

|

x

|

x

|

Miller presence

|

x

|

x

|

|

|

|

|

|

|

|

x

|

Rotational speed at tip

|

|

x

|

|

|

|

|

|

|

|

x

|

Material stress

|

|

x

|

|

|

|

|

|

|

|

x*****

|

Brake is

released

|

x

|

x

|

x

|

|

|

|

|

|

x

|

x**

|

Mill can produce product

|

|

x

|

x

|

|

|

|

|

|

|

x

|

Storm/showers/lighting

|

|

x

|

|

x

|

|

|

|

|

|

x

|

Reference meteorological

station(s)

|

|

|

|

x

|

x

|

|

|

|

x

|

x****

|

Weather maps

|

x

|

x

|

|

x

|

|

|

|

|

|

x**

|

| Absolute wind

speed/direction at mill*** |

|

x

|

x

|

x

|

x

|

|

|

|

x*** |

x**,

***, **** |

Mill cap direction

|

|

x

|

x

|

|

x

|

|

|

|

x*, ***

|

x**, ***

|

Sail type

|

|

|

x

|

|

|

|

|

|

|

|

Turbulence Intensity

|

|

x

|

x

|

|

x

|

|

|

|

|

x**

|

Temperature

|

|

|

|

x

|

|

|

|

x

|

x

|

x

|

Air pressure

|

|

|

|

x

|

|

|

|

x

|

|

x

|

Humidity

|

|

|

|

x

|

|

|

|

x

|

|

x

|

Battery status

|

|

|

|

|

|

|

|

|

x |

x

|

Webcam

|

x

|

|

|

|

|

|

|

|

x

|

x

|

* The implementation

of cap direction (mostly based on magnetometer) needs to be

checked if it works for sporadic manual turning of (Dutch) wind

mills

** These are

measurements seen in 3 or more areas. So important to start with.

*** As the wind

direction equipment is positioned on the cap, the cap direction is

implicitly needed to determine the absolute wind direction.

**** If one wants to

verify wind speed en direction; the values at the mill need to be

compared with reference values at SYNOP/METAR/KLIM

meteorological station(s).

***** Sampling rate needs to be around 10 per

second (per 90deg rotation at least two samples [180end/min and

Nyquist criterium]).

In general all measurements and their results need to be

validated with theory and practice.

Sensors for the measurements

To perform these measurements, the following sensors are possible

(F: fixed; R: Rotating with mill cap or sails; E: Every sensor):

- Two (dry bulb) temperature

sensors (C) [F]

One at cap height and one at ground level (for instance using BME280, BMP280, BMP180, MAX6675 [thermocouple]), measuring the

outdoor temperatures. The temperature difference between the two

temperature sensors can be a warning for a

front. During a 2017 experiment

to determine the optical refraction, the temperature differences

was measured (height difference 2.8m and measurement interval

minimally 10min). This showed that the influence of rain and

fronts could be seen in the temperature differences. So this method

might perhaps be usable for windprediction at windmills.

Tested thermocouple sensors (MAX6675 and MAX31855K). Both have only a resolution of

0.25C, thus not very great.

Have not been able to get the one

type of MAX31855K working (too much interference???). Another

type of MAX31855K is working (althought using the default

CS [D6 on ESP8266] resets the ESP8266 at startup, so now using

D1 [and thus disabling a default I2C interface port).

- Air pressure sensor (mbar) [F]

This to determine the air pressure (for instance using BME280 or BMP180). This will provide an indication

for the going and froing of high or low pressure areas.

- Wet bulb temperature (C) [F]

This predicts the happening of dew on machinery and the human

comfort. Can be derived using BME280, by using humidity [%] and (dry bulb) temperature.

- Revolution sensor (ends/min) [R]

This sensor measures the rotations per minute of the wind

shaft/sails. This can be done with reflection surface, reed

switch or gyroscope sensor (such as MPU-6050) at vertical shaft. This data can

also be offered by/to the Spinning mills

and/or eMills projects.

One can determine what the minimum wind speed (energy) is

needed for the mill to rotate (when turning for de prins

or for production).

- Material stress (deg/sec and m/sec2) [R]

At the tip of the sail stresses can happen (in direction of

rotation, in direction of wind and torsie in the stock).

Measured using gyoscope and accelerometer (e.g MPU-6050) at tip of stock(s). To be used

for preventive maintenance.

The sampling rate needs to be high (sub second level).

Proper calibration of the accelerometer is important.

Use for instance Magneto.

- Mill cap direction (magnetometer, deg) [R]

This (can be QMC5883L

magnetometer) is to measure the direction of the mill cap.

Proper calibration of the magnetometer is important. Use for

instance Magneto.

- Wind direction (wind vane, deg) [R]

This can also be a magnetometer or an absolute angle detector (5

or 6bit; might be too expensive). A commercial weather station

is planned (such as: Ecowitt GW1103) to

determine local weather.

Alternative is using an analogue wind vane together with an ADC port on

ESP32/8266 (such as XDB1002-17 Series with mA output [into 100Ω ||

2.2µF]).

- Wind speed and gust (One to three anemometers, Bft, m/sec) [R]

This is to measure the wind speed. Two on each end of the long

stretcher and one on the mill cap. It needs to be determined

what is the best location for the anemometer at a

wind mill (with a tail). A commercial weather station is planned

(such as: Ecowitt GW1103) to

determine local weather.

Alternative is using an analogue anemometer (XDB1002-15 Series with mA output [into 100Ω ||

2.2µF] or this one which does not need power)

together with an ADC port on

ESP32/8266.

More than one anemometer is handy for determining the

best position of an anemometer at/on a mill.

- Gustfactor (vlaagfactor) and z0 (derived

from anemometer)

This can be derived from the variation in windspeed

(>5m/sec), using Benschop's vlaagfactor [2005a,

section 2.2; 2005b, page 877].

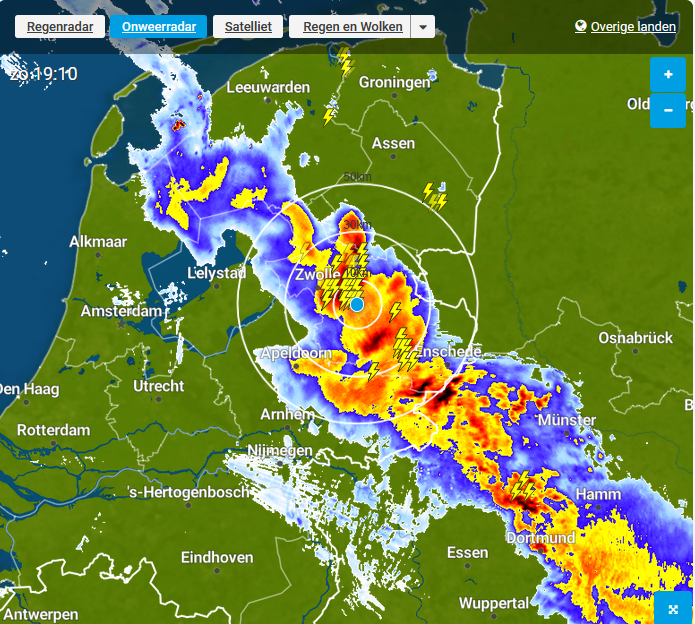

- Lighting detector (distance) [F]

Example of such a detector can be found here (AS3935) and also it can be an MF radio

(around 500kHz). Make sure your powersupply is a linear power

supply (and not a switching power supply [SMPS] as these give

too much noise)

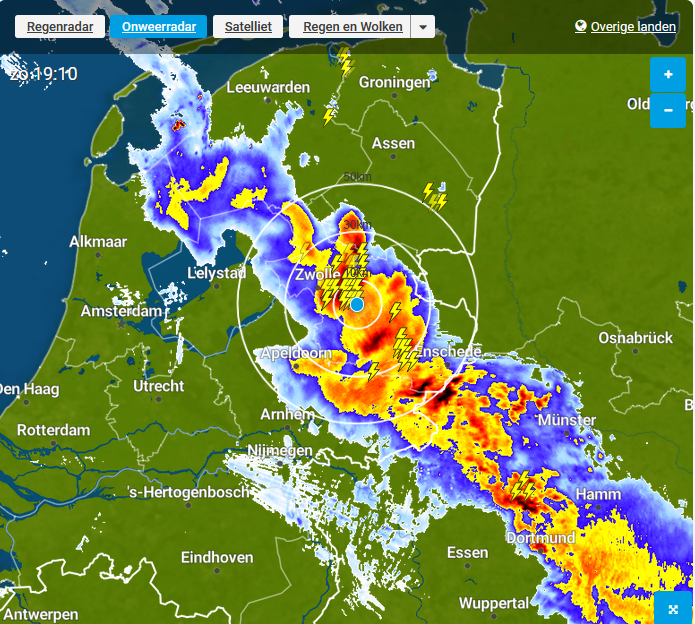

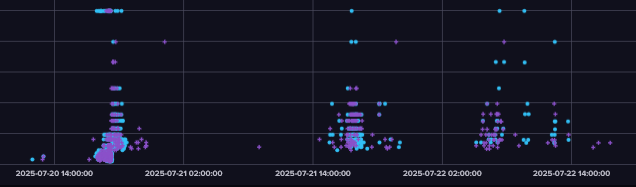

I have the AS3935 (I2C) succesfully tested during a

thunderstorm on 20/7/2025 (using AS3935MI driver).

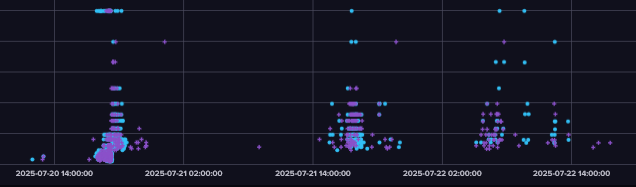

Here are the registrated lighting strokes on 20/7/2025, 21/7/2025 and 22/7/2025 (using

two AS3935):

The high dots are strikes at overhead (1km) distances. while the

lowest dots are at 38km distance.

One can also use one's mobile phone (tested: iPhone SE [no

displayed screen]: the left top of phone between 0 and 3cm from

the AS3935; this generates many disturbers and some lighting

events [the reported km distance is somewhat depending on the

distance between phone and AS3935])

- Battery level (V) [E]

This to allow each sensor to signal if it has enough power, say

for the coming week (using ADC port of processor); if not it

should warn the outside world. Interpreting battery level might

not be very reliable though.

- Miller presence indicator [F]

This will show if a miller is present. Can be a reed switch at

the main door to the mill.

- Brake release indicator [R]

This will show if the mill can be producing (aka the mill is

allowed to turn). Can be a reed switch at the pawl or brake

beam.

- Webcam [F]

To show the mill from the outside. High speed Internet

connection is needed.

- Meteorological stations' wind speed and direction sensors (F)

To cross reference mill data, wind data of at least three

meteorological stations (KNMI acknowledged) needs to be

available through WebServices.

Processor at the sensor

Each (or a combination of) sensors will have a processor (such as

ESP32, ESP8266, Wemos, etc) and a WiFi connection. Preferable the

sleep mode of each sensor should be used (to reduce power

consumption).

Below remark can be handy

in case of reed switches:

The anemometer and rain sensors in my weather station 2 use

reed switches. To achieve low power, I had to use a second, low

power processor chip to monitor the reed switches while the

Wemos was in deep sleep.

Power for sensors

Some sensors (that are not in the mill cap, also reducing

lighting strikes) will be connected to the mains. The sensors in

the mill cap might be powered using: solar cells, wind turbine

and/or batteries or using reliable drag contacts.

Connectivity within the mill

Each sensor has a WiFi connection (and if possible all sensors

are meshed together in a WiFi mesh [like

ESP-Mesh], one WiFi-ed sensor [perhaps in a mesh] can reach

the outside world).

In case we want to measure Material stress some bandwidth needs to

be available: 6 float variables (acceleration [xyz] and angular

velocity [xyz]) and time . There will be some 15 Bytes JASON

overhead and some 40+45 Bytes MQTT overhead (in total some

110Bytes, quite a lot). So that is at least some

(7*4+110)*10*8bit/second : ~11kbit/sec. One could also store it on

a 8GByte SD card, would be worth of 325days of data.

If a webcam (high

speed WiFI), a fixed Internet or unlimited 4G SIM is needed (due

to link to streaming services).

If only a

magnetometer (LoRaWAN), revolution (LoRaWAN) and there is TTN (The

Things Network) access; no LoRaWAN gateway is needed.

If magnetometer

(LoRaWAN), revolution (LoRaWAN) and local weather station (WiFi),

a LoRaWAN gateway, is needed.

If LoRaWAN

gateway, one can use 4G or fixed Internet. If local weather

station needs a lot of bandwidth: a (un)limited SIM might be

needed (instead of a smartmeter SIM).

Extendibility/modularity of the mesh

Adding sensors to the mesh should be as easy as possible. At this

moment, when a sensor is connected, it will be included in the

platform.

Connectivity to the outside world

An Internet router (using: fixed, 4G or LoRaWAN) with the WiFi or possibly

the use of a wireless mesh (ESP-Mesh). Thus providing access to

database in the cloud using MQTT.

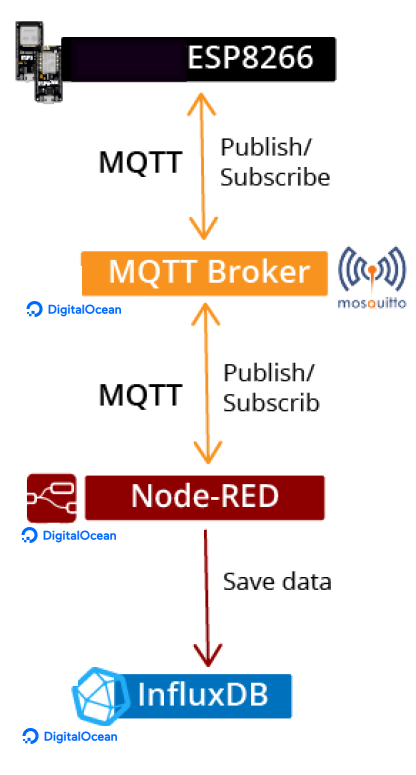

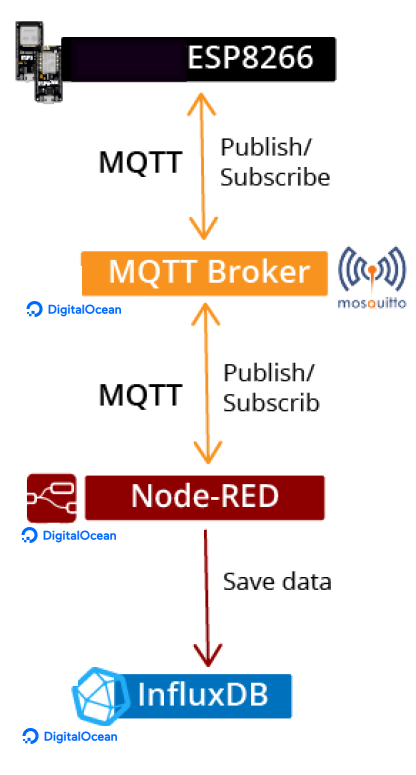

Software platform in the cloud

It would be nice if the smartmolen, Spinning mills and eMill projects are incorporated in

all of the above. Using some ideas (like Mosquitto, Node-RED and

InfluxDB on DigitalOcean) from this eBook. It is expected

that per mill one needs at max. some 10MByte additional storage

per month (120MByte/year).

Remark: The amount of Bytes needs to be

determined over the coming time.

Installation, support and maintenance

Clear agreements need to be made around this. Quality and

flexibility of the platform (at mill, cloud and service),

trustworthiness of the party managing the SlimmeMolen service,

confidence that the service will exist for a long time (5 to 10

years), good balance between costs and quality, support party that

is eager to do innovations.

Cost of SlimmeMolen sensors and services

Costs around: equipment, installation, support, maintenance,

cloud services, web services. A cost overview (using input from

smartmolen project) has been made based on: equipment,

support for a x year project (incl. CDF services), and a possible

student with academic links.

Linking with

weather prediction

Doing one's own measurements helps to support the interpretation

of weather prediction. So including an overview of weather

predictions (like KNMI weather charts

and service like Windfinder) are

important for the SlimmeMolen platform. See for some further

examples here.

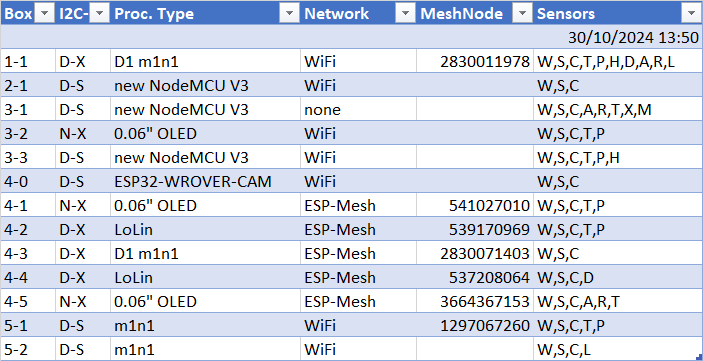

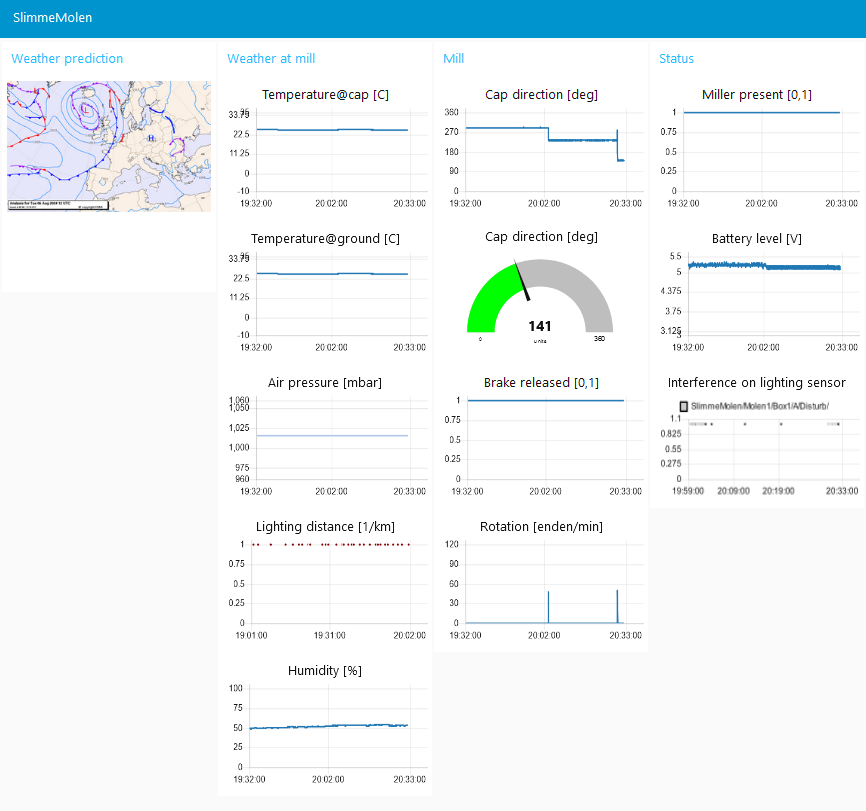

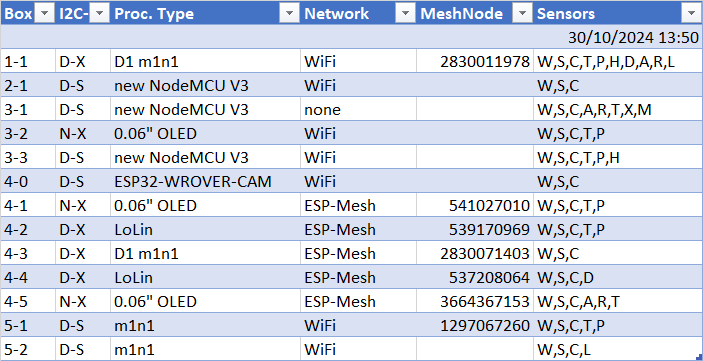

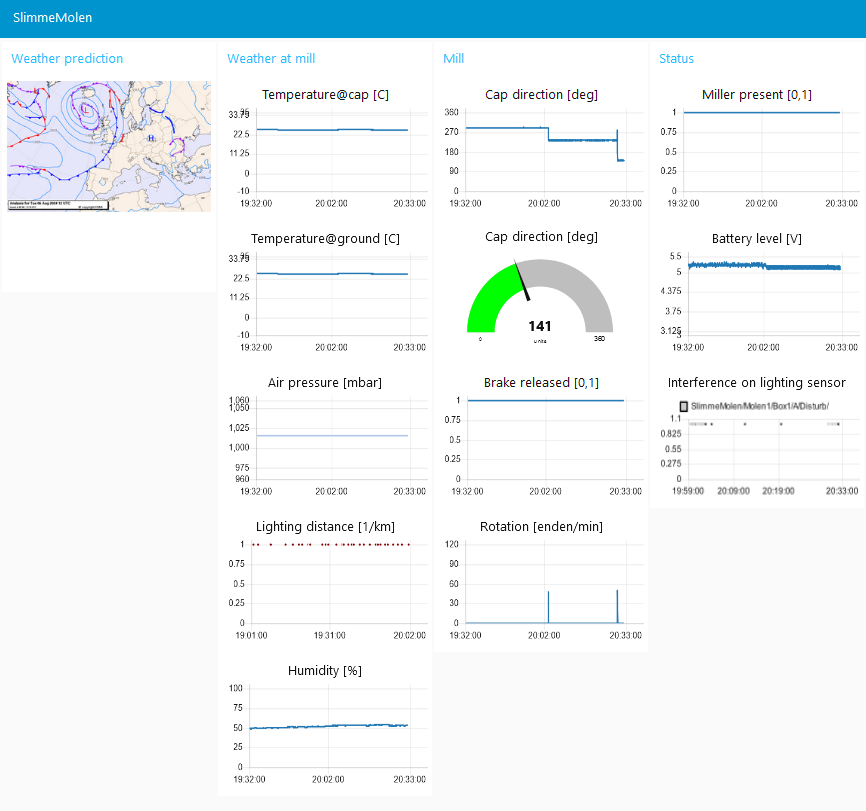

The SlimmeMolen prototype

At this moment we have the

following IoT devices to prototype the SlimmeMolen platform: an

ESP8266 D1 Mini (Molen1, incl. WiFi to Internet), an

ESP8266 NodeMCU (Molen2, incl. WiFi to Internet); three

ESP8266 NodeMUC (Molen3, incl. WiFi to Internet) and four

ESP8266 plus one ESP32 (Molen4 incl. gateway between

ESP-Mesh and Internet).

These IoT devices send MQTT messages from the

following sensors: Temperatue&Humity&air Pressure

(BME280 and BMP180 [no humidity]); cap Direction (QMC5883L*); Acceleration and Revolutions

(MPU-6050); Lighting strikes (AS3935); presence Switches

(GPIO12 and GPIO14 of ESP8266); Real Time Clock X

(DS3231); Micro SD card; Battery status (ADC of

ESP8266); and WiFi or ESP-Mesh field strength (WiFi of

ESP8266).

Here is an overview of the boxes configured and running:

The IoT devices communicate through WiFi or ESP-Mesh; depending

which is possible/wanted.

The IoT devices' software has been built in such a way, that one

can include the sensors, I/O devices and local network one wants

at a mill (each processor will figure out itself which sensor(s)

it has). If there is no WiFi or ESP-Mesh connectivity, it can

still display the measured info on an local LCD (if plugged in) or

store on micro SD card.

The generated JSON data can be seen in Node-RED UI, InfluxDB (own server and

on Influx Cloud); on an LCD or OLED display; on a terminal

connected to the ESP8266s/ESP32s; or on a micro SD card.

The below trial setup has been build up to now (for

ESP8266/ESP32 setup see here).

Real-time graphs generated from boxes with several sensors (at

this moment positioned at home) can be seen below.

The InfluxDB has been added (also running on DigitalOcean) to

store all (some 30) measurements at an interval of 10 seconds.

This to investigate the possible drift of the magnetometer over

two months time. Hopefully we can also measure temperature

gradients between a low and a high position with Molen4's

two temperature sensors (to check a theory of mine around

low pressure areas).

Experiences with the SlimmeMolen

prototype

The following experiences were registered (for most bullets the 'molen'

was in rooms of the house):

- General evaluation of the prototype:

- IoT devices, handy for the wind mill environment, were

succesfully implemented.

- The cloud services (with MQTT server [mosquitio],

programming tool for event-driven applications

[Node-RED] and database [InfluxDB]) behaved stable for some 30

days.

At a certain moment memory usage steeped up to 100%. I deleted

the largest data file and now InfluxDB, Node-RED and Node-RED

dashboard are accessible again.

Need to determine why the InfluxDB database grows fast

(the first 55 days of InfluxDB data 4GByte and the last

few 10 days around 100MByte/day/2mills, we need to compare

this to the 4.5MByte of JSON messages that are generated

with the Boxes/day/2mills; why is there a difference of a

factor of 20!?)...

- Slowly (after the first 12 days) the IoT devices got more

and more stable (looking at software updates and hanging

devices). Sometimes a single sensor on an ESP8266 stops, while

the others continue. But after some 20 days it now looks all

ok.

- WiFi provides a stable network and connectivity to the MQTT

broker.

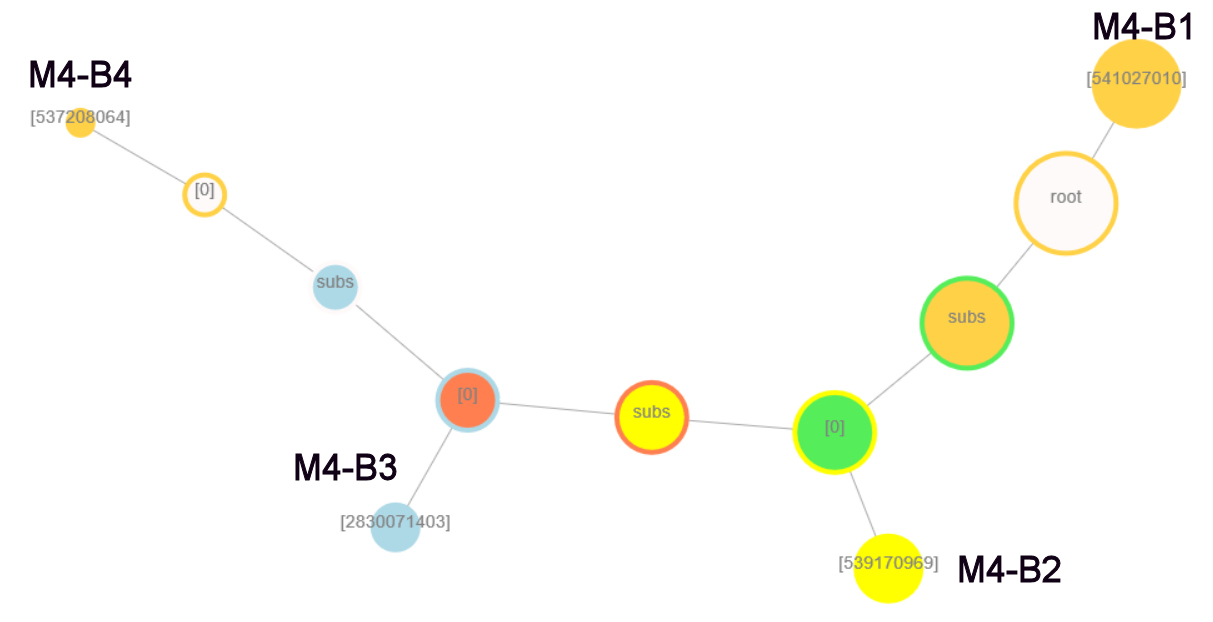

- ESP-Mesh is

working (there is still some lack of convergence). Its

interconnectivity with Internet is implemented using one

ESP8266 (as master on ESP-Mesh side) and one ESP32 (as slave

on Internet side).

- ESP-Mesh improves the coverage, due to its inherent meshing.

When having an additional intermediate node, the range is

increased (so one intermdiate node: double distance to gateway

node, two intermediate nodes: triple distance to gateway node,

ect.).

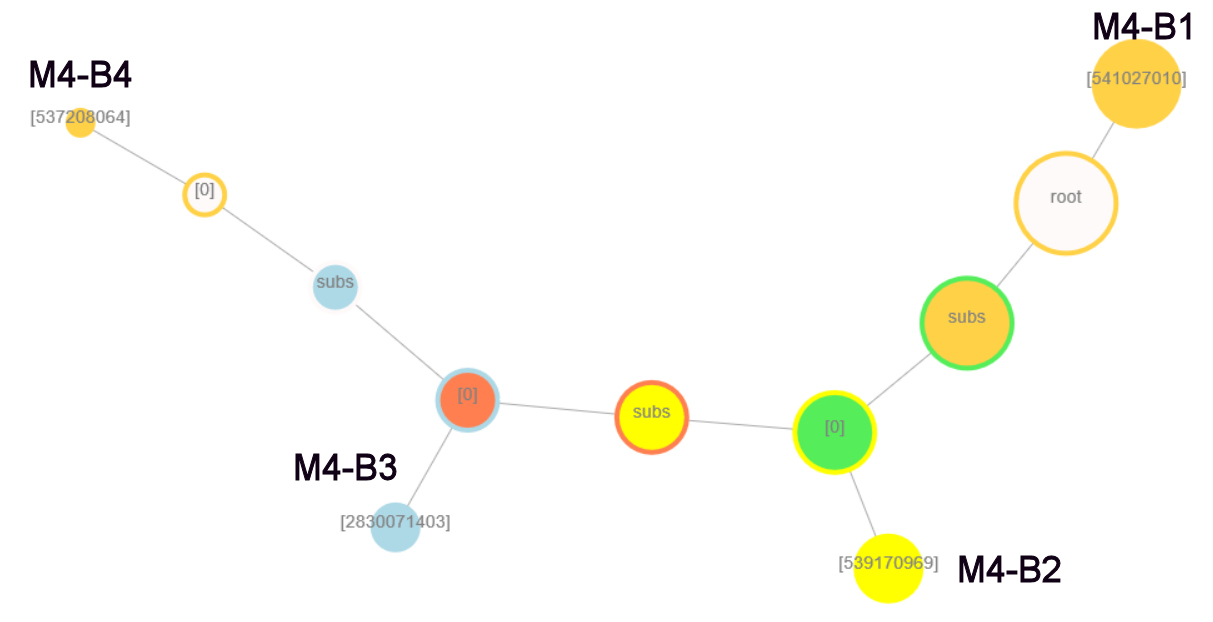

Here is a sample ESP-Mesh network (of Molen4, with

four boxes B1 to B4):

B1 (the ESP-Mesh gateway) is conncted to the Internet.

- It looks the maximum message size of I2C packet

is 128Byte (while it should be much much larger). I experience

this when sending data from ESP8266 to ESP32 (over an I2C link

using Wire.h). The maximum message size of I2C? is

indeed 128Bytes (#define

I2C_BUFFER_LENGTH 128).

Remark: For now split the messages (but perhaps

recompile Wire.h is better).

- The MQTT maximum packet size, which is by default 128Byte (my

experience is not 256!). If needed, increase this

buffersize (setBufferSize).

- Make sure that the keepalives (setSocketTimeout and

setKeepAlive) in MQTT are set according to the

measurement interval of sensor readings (aka MQTT messages).

- Application experiences

- InfluxDB needs considerable free disc memory (when not

enough disc space, the whole systems becomes very slow) and

also is greedy on RAM memory (minimum 1GByte needed).

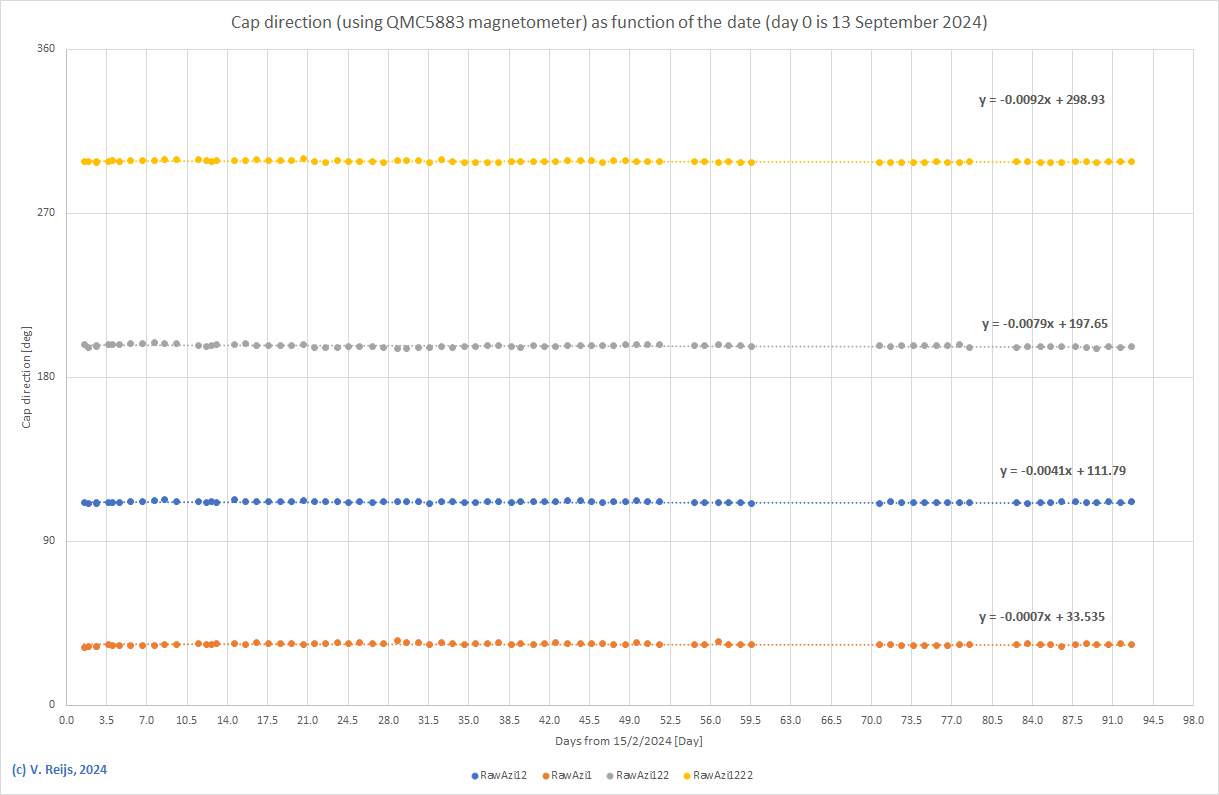

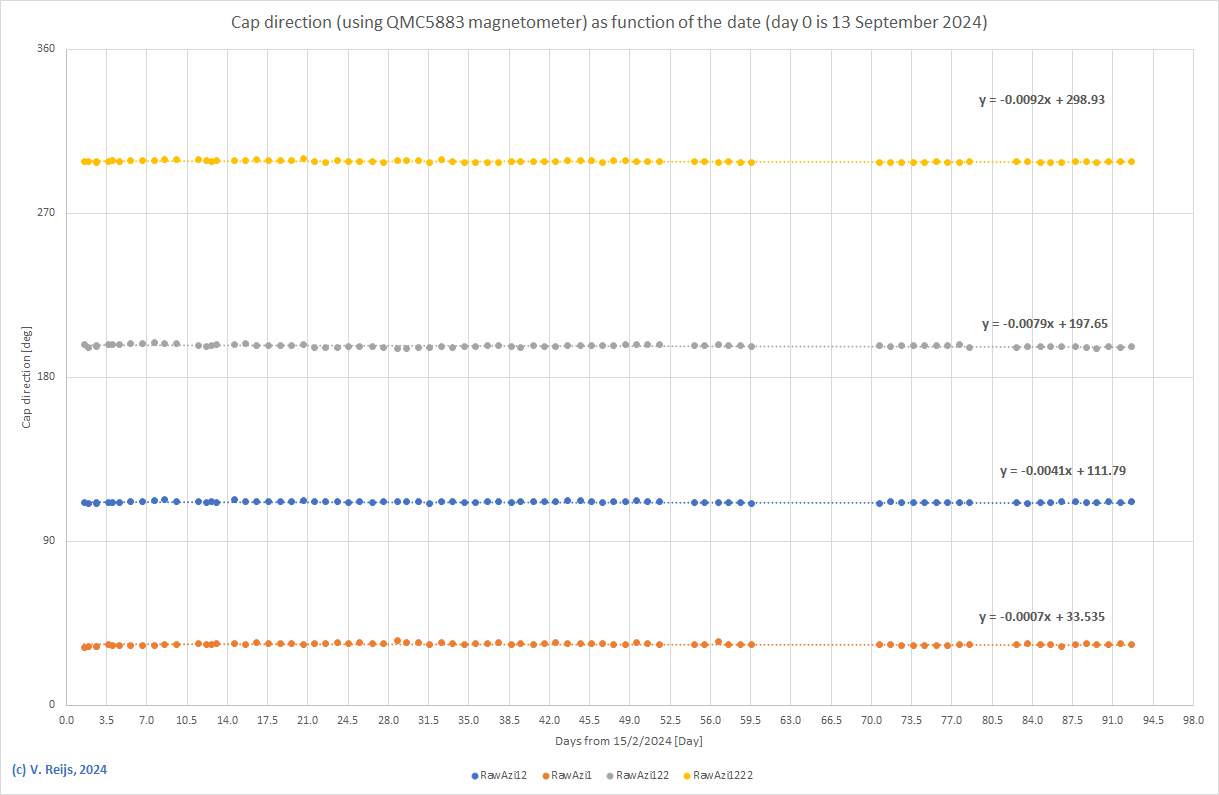

- Sensor evaluation for four directions:

- It looks the direction readings (magnetometer QMC5883) have some drift for certain

direction(s):

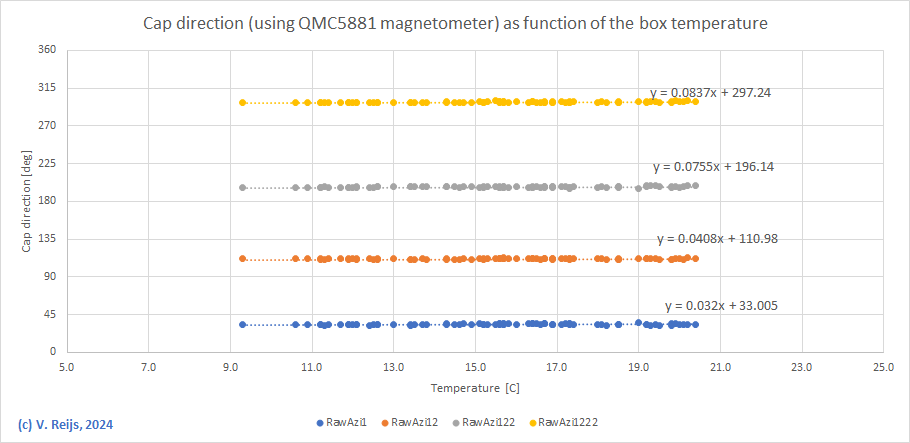

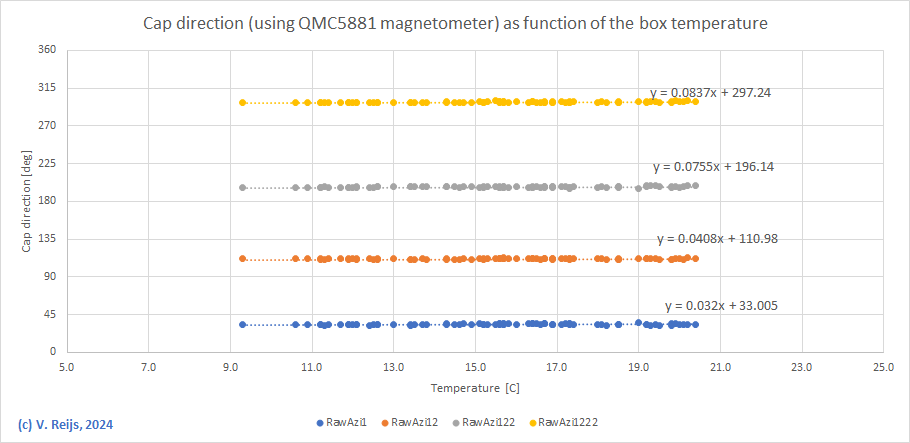

- Stability looking at the temperature

of magnetometer (QMC5883):

- If using the data between 15/9/2024 and 15/12/2024, and we

optmise for temperature and date we get the equation:

Dir = a1 * Days + a2 * Temp + b [deg]

Dir

|

a1

Days from

13/9/2024

|

a2

Temp [C]

|

b

Dir @ 0C &

13/9/2024

|

1σ

|

4

|

-0.003

|

0.06

|

297.7

|

0.6

|

3

|

-0.003

|

0.05

|

196.6

|

0.7

|

2

|

-0.002

|

0.03

|

111.3

|

0.5

|

1

|

0.001

|

0.02

|

33.1

|

0.7

|

So no signifcant influence due to the date of measurements

(which is as hoped/expected), The temperature has some

influence. From above table: 10C some 0.4deg direction change.

Looking at the sensor's specs: which has

is 0.05%/C; this would results per 10C in a direction change

of some 0.15deg. So they are in the same order.

- It would be good to test the

LMS303DLHC or BMX160 (which is used in the smartmolen

project). Not planned for this prototype.

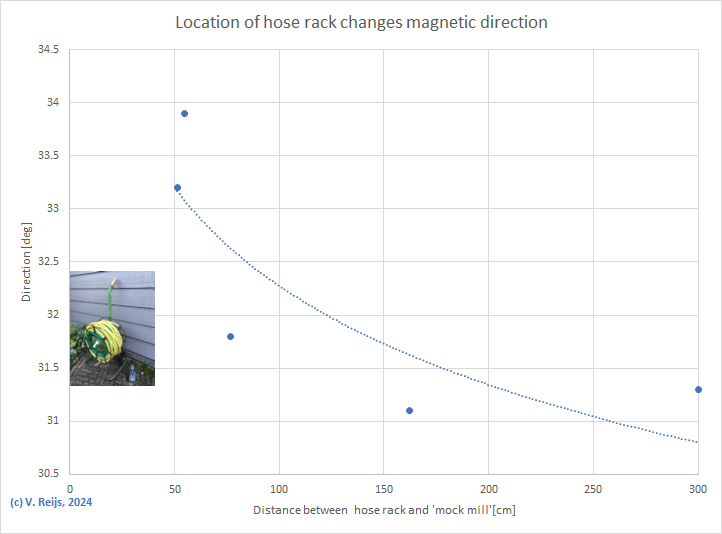

- Even a small screw (at a distance of some 10cm) or vacuuming

(at some 60cm) can change the direction with a few degrees. A

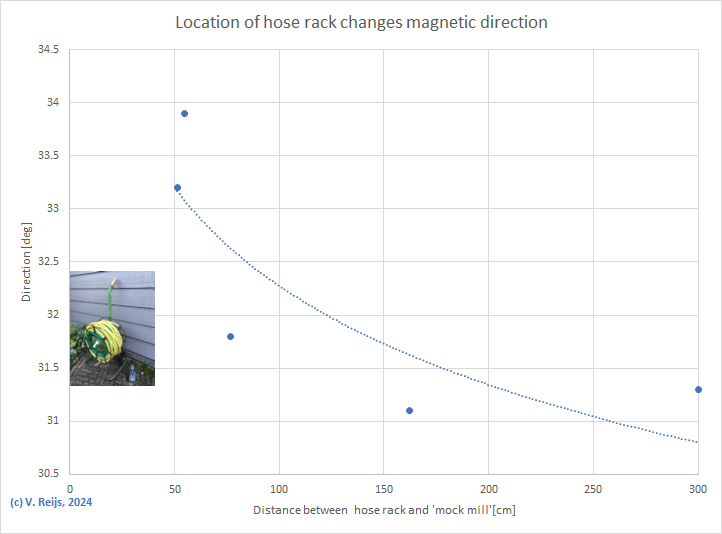

metal hose rack was on the other side

of the shed wall and its influence depending on distance can

be seen here:

A variation of some 3 degrees can be seen. So make sure your

magnetometer is as far away as possible from hard and soft metals.

So watch out for metal in the cap of the mill (brake wheel,

wind shaft, winding mechanism (rolls, rails, etc.), support

structures, etc.)!

- Remark: on the Internet BME280 and BMP280 are many times

mentioned together in e-shops. But be aware the BMP280 can

only do temperature and pressure, while the BME280 does

temperature, humidity and pressure! They also need different

libraries!

- Some integrated OLEDs on ESP8266 use the default I2C

GPIO ports (SDA=D4, SCL=D5) while other use different ones

(SDA=D14, SCL=D12)!

- Experience gained with the lighting detector is not yet

fully satisfactory.

The capacitor (parallel to the antenna) is too

large in one sensors I have, so calibration did not work (see at the bottom of

this link). I have informed the shop about this; they

plan to send me a new device. In the meantime I replaced the

existing capacitors with some 970pF (I am though not that good

in SMD soldering...). Now the calibration looks more robust.

BUT: over the days the capacitance or inductance

(aka resonance frequency) seems to drift! The trend (of Molen5

and Molen1) of the drift can be followed on the dashboard.

Remark: Need

to check the sensor (AS3935) during thunder

storms. Hopefully in the coming

autumn/winter weeks.

- WiFi/ESP-Mesh coverage (aim to have excellent/good strength

in/near the mill body):

- The WiFi /ESP-Mesh distance range is not large (with some devices

only 5m, in other devices around 15m); one wall/floor

already reduces 50% of the needed field strength. Most ESP8266

development boards do not have a large WiFi dynamic range.

- Determine the influence of an external aerial.

This is not easy to compare, as the WiFI RSSI value is quite

variable. Had a two ESP8266 D1 mini (ESPa [with different

aerial configurations: Box 5-1] and ESPb [always on board

aerial, Box 5-2]) and one ESP8266 D1 Pro mini (ESPc with

external aerial). The aerials were on the table (some 10cm

between them two) and some 5m from repeater.

Four aerial confurations for ESPa and ESPc were tested: on

board aerial; only aerial cable (19cm long); short (19+8cm)

aerial; long (19+18cm) aerial.

Aerial of

ESP-1

|

RSSI

ESPa

|

RSSI

ESPb

|

RSSI

ESPc

|

RSSI

Difference

|

Test 1 (both

on board)

|

on board

|

-57

|

-59

|

|

2

|

Test 2a

(ESPa cable inline with aerial)

|

only aerial

cable

|

-50

|

-60

|

|

10

|

+short aerial

|

-49

|

-60.5

|

|

11.5

|

+long aerial

|

-48

|

-59

|

|

10

|

| Test 2b

(ESPa cable inline with aerial) |

only aerial

cable

|

-49

|

-55

|

|

6

|

+short aerial

|

-49.5

|

-56.5

|

|

7

|

+long aerial

|

-47

|

-57

|

|

10

|

Test 3 (ESPb

cable perpendicular to aerial)

|

only aerial

cable

|

-52

|

-61

|

|

9

|

+short aerial

|

-49.5

|

-62.5

|

|

13

|

+long aerial

|

-48.5

|

-62

|

|

14.5

|

| Test 4 (ESPc

with external aerial) |

| only aerial

cable |

|

|

-58.5

|

|

| +short aerial |

|

|

-59

|

|

| +long aerial |

|

|

-64

|

|

As you case there is considerable variation. But on average an

external aerial (including the cable) give some 8 (between 5

and 12dB) improvement, seen from an onboard aerial. This migth

result in some 2 to 6m more in distance (assuming normal

distance of WiFi is 10 to 30m).

ESPc has a much worse sensitivity than ESPa and ESPb.

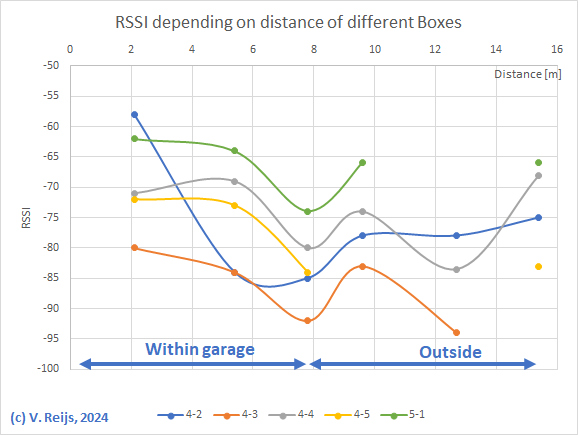

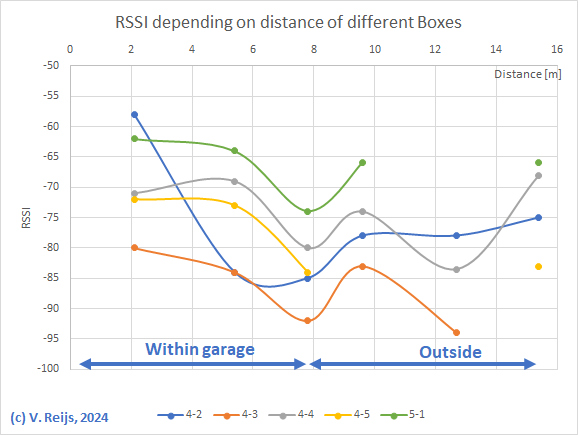

- Several boxes were tested on their

sensitivity. Box 5-1 has an external antenna, while the other

boxes have the integrated antenna. The access point (Box 4-1)

was at the end of the garage (0m) and the other Boxes under

test was moved through garage into the outside (upto around

15.5m).

Remember that RSSI is not defined in dBm

(but something proprietary). When no connectivity was seen, no

point/line is seen in above graph.

At a distance of some 7m (at start of the garage) the RSSI

reduces for all boxes, but when moving the boxes outside the

garage, the RSSI increases somewhat. Interestingly two boxes

(4-3 and 5-1) were seen at some 15.5m, while for shorter

distances they were not seen...

- Longer convergance tests are

needed with the ESP-Mesh, when nodes are

added/removed/restarted. This is now looking better (after

including MQTT timers and restarting an ESP-Mesh if a long

time only 1 node in an ESP-Mesh). The convergence can take 1

to 15 min or more! for an ESP-Mesh of five nodes....

A new version of ESP-Mesh was made for me (1.5.4). It now

converges much faster (1 or 2 minutes for 5 nodes). But

there is still some instability...

Need to check how stable this new version is in the coming

weeks.

- Battery life (aim a quarter or half a year):

- Using WiFI, ESP-Mesh and other chips on the ESP8266

development boards use much power (a WiFi module needs between

60 and 90mA; and the other chips around 4 to 20mA). Sleeping

IoT devies will thus still see around 4 to 20mA; still a lot

on average.

Perhaps better to use the ESP-12F (or

ESP32 variant?), but it is not expected that this will

be prototyped.

- It looks that some device brands

don't revive after a Deep Sleep. I was able to get it

working for a few device source.

I have informed the shop(s) about this.

- Deep Sleeping can only be used effectively if there is no

hopping/meshing happening. Leaf nodes tothe mesh can be

Deep Sleeping (like the one in the rotating mill cap).

- Alternative is to use mains where possible, this is

difficult for devices in the rotating mill cap!

- To improve battery life; LoRaWAN

should be a better alternative then WiFi and/or ESP-Mesh.

It is not expected that this will be

prototyped.

- Cost of the prototype

Eight ESP8266 (@ ~3Euro), one ESP32 (@ ~6Euro), ten sensors (@

~5Euro), two breadboards (@ ~2Euro), USB and jumper cables

(total ~10Euro): total around 100Euro.

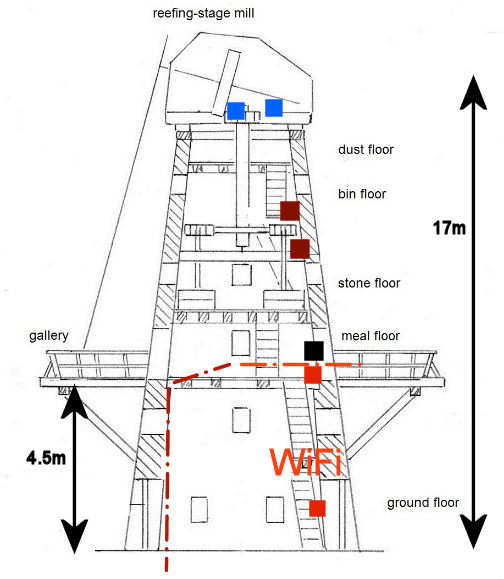

- Experience at actual wind mills

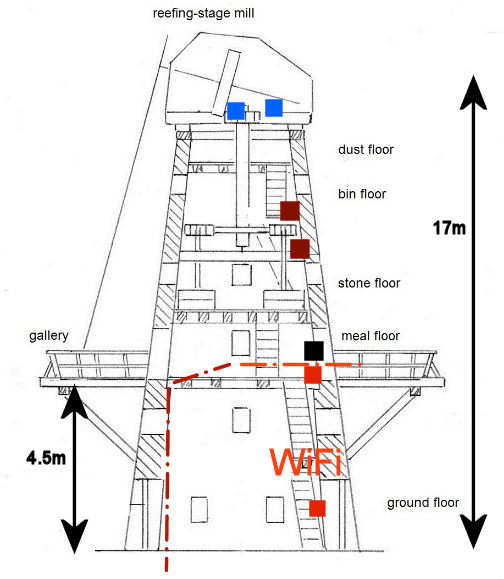

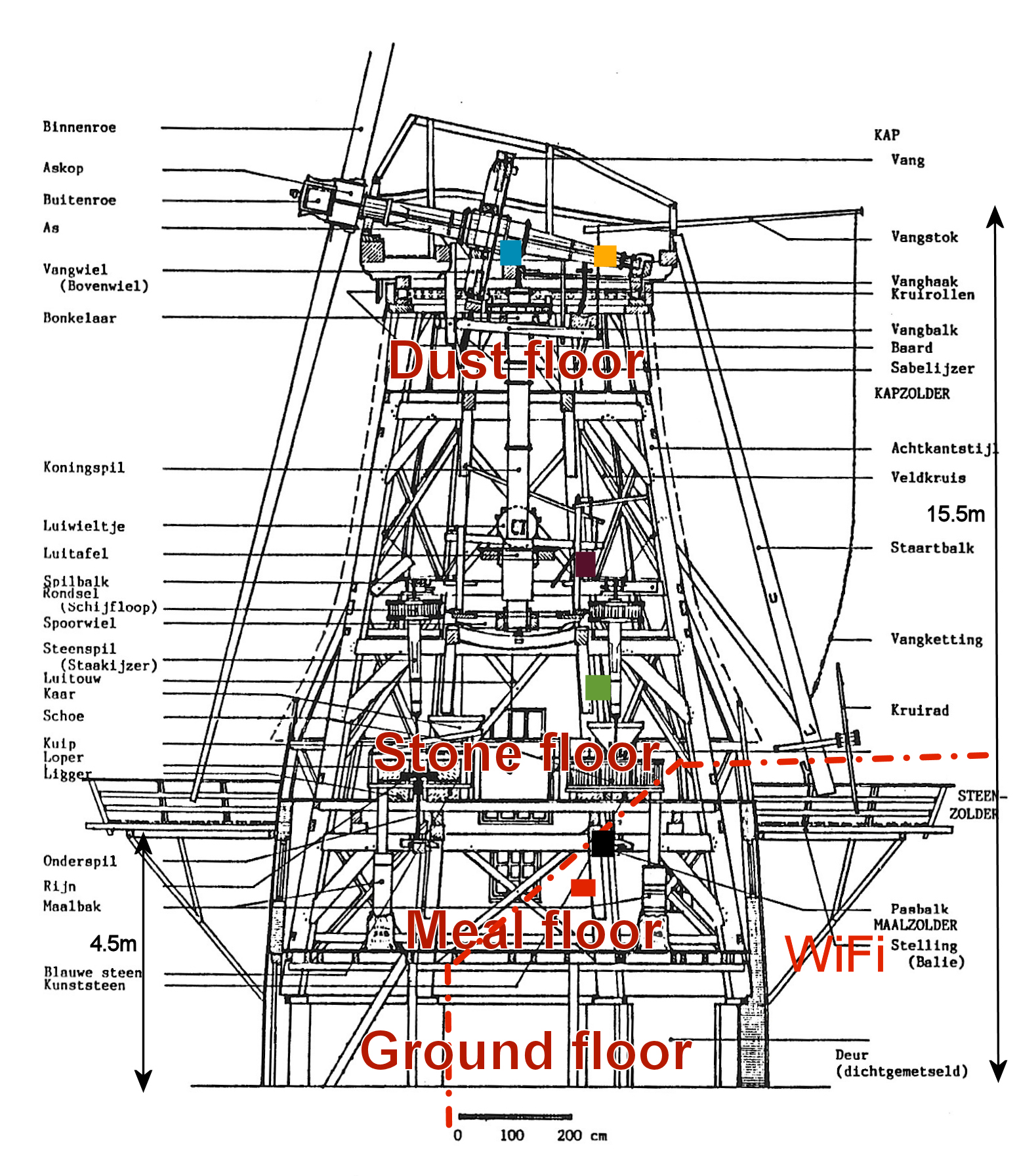

- Four boxes with sensors (Molen4)

were placed at De Zwiepse Molen

on Sept. 7th, 2024. Molen4's data could have been seen

live at this dashboard.

- Sensor boxes at:

- the ground floor (red: first

temperature/humidity/pressure sensor, miller presence and

gateway between WiFi/Internet and ESP-Mesh; connected to

battery);

- half way the meal floor (black: act as repeater;

connected to mains);

- the stone floor (brown: second temperature

/humidity/pressure sensor; connected to mains); and

- dust floor on the beam or on the wallover (light blue:

magnetometer, brake release, lightning detector; connected

to battery).

- Internet was available with WiFi up to the bottom part of

meal floor. Mesh-ESP was used between the four boxes.

- Most of the time the ESP-mesh was stable. By slight

rearranging the boxes the connectivity was made stable.

- Once in a while the connection with the MQTT server (on

the gateway) was lost, but the system reconnected

succesfully. Reason yet unknown (WiFi connectivity was

available).

- Box on the left beam did not connect, but on the right

beam and on the wallover it connected. Perhaps the stone

floor box (brown) should be on the bin floor or on the

fixed dust floor itself (also better to get a higher

position for the second temperature sensor).

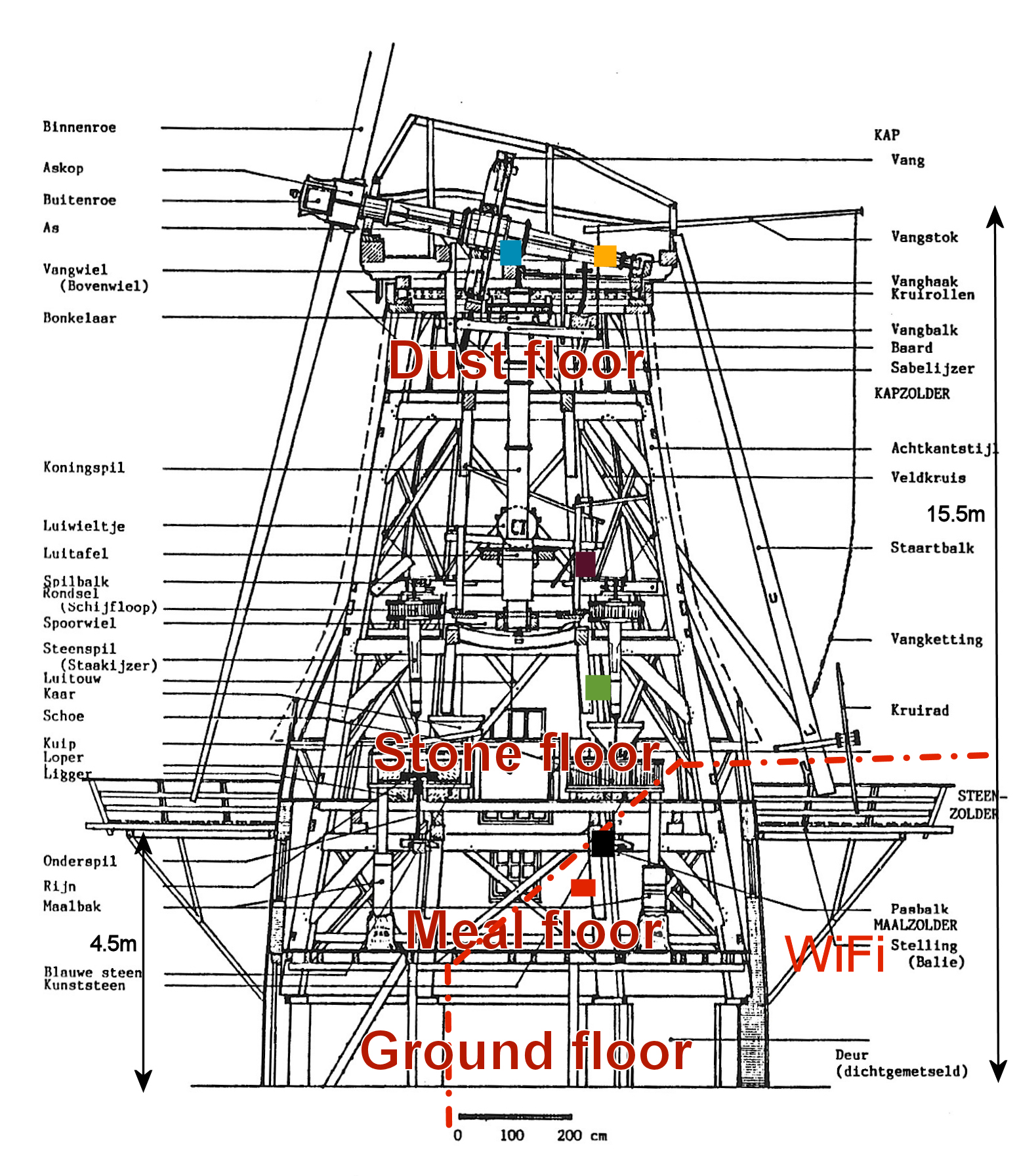

- Fifth boxes with

sensors might be placed at Westermolen on Sept. 21st and 28th,

2024.

- Tests on 21 Sept:

- at height of sack hoist friction table (5-1

purple: act as repeater; connected to laptop battery);

- on the windshaft (4-5 yellow: rotation; connected to

battery);

- Experience:

- Internet connectivity (WiFi) is available at the table

on the meal floor.

- Box 4-5 rotated with the windshaft (although during

the tests the windshaft only rotated once or twice:-(

- First Box 5-1 was on top of the hopper, ESP-Mesh RSSI

around -90 (~8m distance); this resulted sometimes in

losing connectivity. Then moved Box 5-1 to the

height of the friction table, this resulted in a

ESP-Mesh RSSI of -60 to -70 (~5m distance; depending on

position of Box 4-5 on the lowest or heighest point of

box/jar on the shaft). Connectivity was satisfactory.

- Tests on 28 Sept:

- Sensors:

- at the table of the meal floor (4-1 red: first

temperature/humidity sensor, miller presence and gateway

between WiFi/Internet and ESP-Mesh; connected to

battery);

- half way up the meal floor (4-2 black: act as repeater

with no sensors; connected to mains);

- half way up the stone floor (4-3 green: act as

repeater with no sensors; connected to mains);

- at height of sack hoist friction table (5-1 purple:

act as repeater with no sensors; connected to battery);

- dust floor on the beam (4-4 light blue: magnetometer,

brake release, connected to battery);

- on the windshaft (4-5 yellow: rotation, accelerator

and third temperature; connected to battery);

- Experience:

- No connectivity was possible with the database

(InflxDB) in the cloud, as there was a problem with that

cloud-service.

- For a short time (3min!) all but one box had

connectivity to the ESP-Mesh towards the Internet.

Except Box 4-3; it was not included as there was a

direct ESP-Mesh connection between 4-2 and 5-1

('skipping' the Stone floor).

- But it was not a very stable connection. After moving

a box, the maximum number of Boxes seen was 3 (instead

of 5).

More study/experience would

be needed to get this stable. This

stability of the ESP-Mesh was unsatisfactory;

new software have been received in the meantime.

Duration tests are being performed. Perhaps

using LoRaWAN (which is expected not to be tested

with this prototype).

- So it was possible to get every sensor box involved.

- One a rotation as high as 71.7 ends/min was recorded

by Box 4-5 (there was wind force 4Bft).

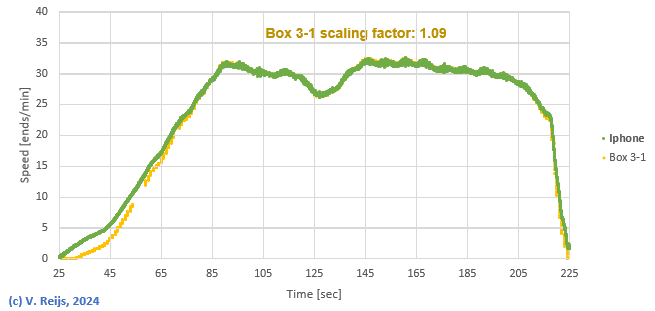

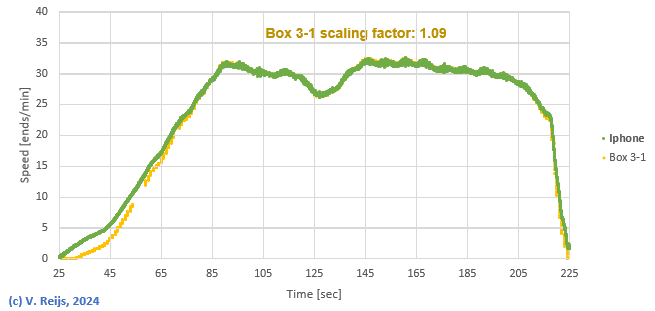

- The acceleration

and rotation (using Box 3-1) was measured at the tip of the

sail (at De Zwiepse Molen on Oct. 2nd). The ESP8266+sensor

(MPU-6050) and an iPhone (with the Sensor Logger App)

simultanously measures these; to compare the results. De

MPU-6050 was sampled 10times/sec, while the iPhone was

sampling at 100times/sec.

The offset (at rest) of the MPU-6050 rotation's magnitude

readings has been removed. Furthermore a scaling factor of

around 9% on the MPU-6050 readings was needed to get the same

magnitude rotation readings as with the iPhone. A 3% scaling tolerance

is mentioned in the MPU-6050 spec.

At speeds above around 20ends/min the values look to match,

below that the MPU-6050 differs more from the iPhone. It has

not yet been determined which of the devices was closest to

reality. There migth be non-linearity in one of the devices

(in MPU-6050 specification non linearity is around 0.2%).

If we compare the acceleration of iPhone

(uncallibrated) and ESP8266+sensor, we get:

The forms of the curve look similar. Both the

iPhone and the ESP8266+sensor are uncalibrated. Calibration

would be needed. Remember that the sensor-chips of the two

devices migth not have been aligned in the same way, so some

differences in x, y and z are likely have happened.

For this prototype the

accuracy of acceleration and speed is ok-ish, but it is

expected improvements (by calibrating) can be made.

- Measure

temperatures at different heights and see how this

links with low pressure regions

and rain

Problemen

- Lost WiFi connectivity

Distance too long (in new situation). The moisture/humidy level

could have been too high (see white

power). Use Contact spray.

- White powder on the PCB

Humidity/moisture is a logical reason (as the procesoors are

outside in open air). Use Contact spray. The ESP8266s were out

almost a year.

- A lot of Noise or Disturbances on AS3935 (M1B1, M5B2)

This is likely to be the noise coming from the switching power

supply (SPMS [Switched-Mode

Power Supply]). One needs to use an analogue

(non switching) powersupply. Or add ferrit on the power supply

lead (not tried yet).

- DuPont/jumper wires

These are nice for eperimenting, but not good enough for

operational service (connects are sometimes flacky). Use

soldering.

- The USB battery bank (13wH: 2600mAh) had a lame USB connector

(Nov. 2025)

- The outside isolation of cable towards the USB Type A

connector breaks (due to cold and/or due to bending when

replacing rechargeable battery?). Buy better cables or reenforce

with self-vulcanizing tape.

- USB micro male connector of cable becomes loose on the BCP USB

micro female connector on the ESP8266 (M3B3).

The springs on the cable's USB micro don't function properly.

- Sometimes the readings of temperature, pressure and humidity

(M5B1) stays the same for considerable time (upto 2 to 7hours).

Need to investigate

References

Benschop, Henk: Representativiteit windmetingen, in het

bijzonder op luchthavens. In: (2005a), issue KNMI Technisch

Rapport TR-277.

Benschop, Henk, Meulen Jitze van der: Quality and representativity of wind

measurements. In: (2005b), Instruments and Observing Methods

Report No. 82: Papers presented at the WMO Technical Conference on

Meteorological and Environmental Instruments and Methods of

Observation, WMO/TD-No. 1265, pp 876-886.

Acknowledgements

I would like to thank people, such as Justin Coomb,

Rien Eykelenboom and others for their help, encouragement

and/or constructive feedback. Any remaining errors in

methodology or results are my responsibility of course!!! If you

want to provide constructive feedback, please let me know.

Major content related

changes: March 21, 2024