CFD tips for a traditional windmill environment

CFD tips for a traditional windmill

environment by Victor Reijs

is licensed under CC BY-NC-SA 4.0

Introduction

This page gives some requirements how to configure one's own CFD

simulation. It is built around the 10 tips of Blocken [2015] and

feedback from others.

There is a slight bias for SimScale (based on OpenFOAM) in these

tips (but it is written in such a way that one can figure it out for

other CFD software).

Several questions are

outstanding, see below purple text. If you have input, please

let me know.

The wind mill environment

On this web page we will be looking at a traditional wind mill

(normally a diameter of ~7m, height of ~25m and sails span of ~22m;

there are of course many variations;-) in a urban environment

(although a more pastoral environment migth also be the case). So

not many high buldings around (say up to 12m high) and hopefully

also no high trees (say an z0 around 0.5 to 1m), but the

build and green environment can be changing. And here CFD will be

helpful to simulate the influence of new buildings and/or growing

trees.

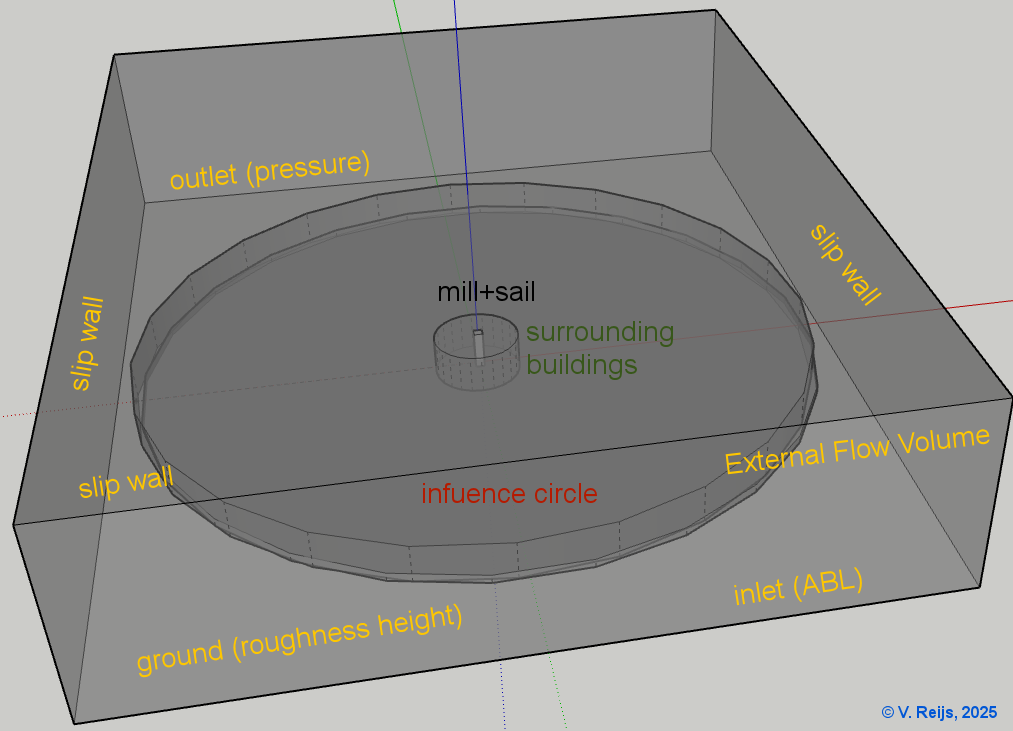

At present a circle with a radius of 400m around the mill is chosen

to evaluate the wind mill biotope (Influence circle). This will also

be proposed for the CFD simulation.

An anemometer could be placed on/near the wind mill to record wind

speed/direction. The space for the rotating sails is of importance

as this will provide an impression of the available power.

The space for the rotating sails could be evaluted using Rotating Zone, but no experience yet has been gained on this.

Requirements

Building model

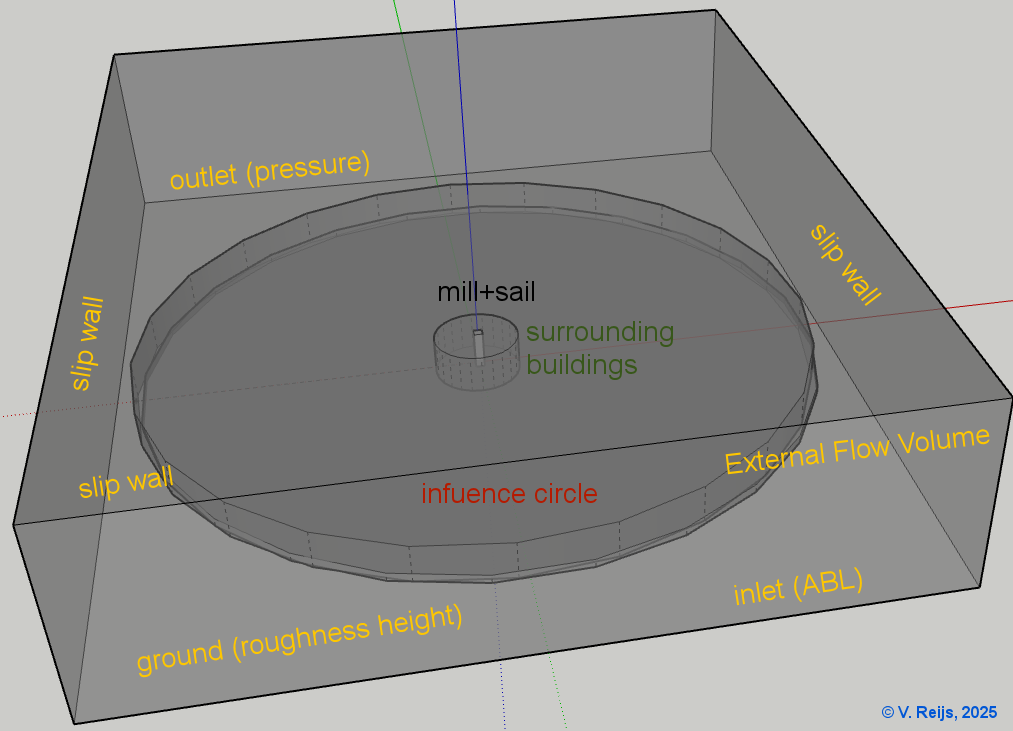

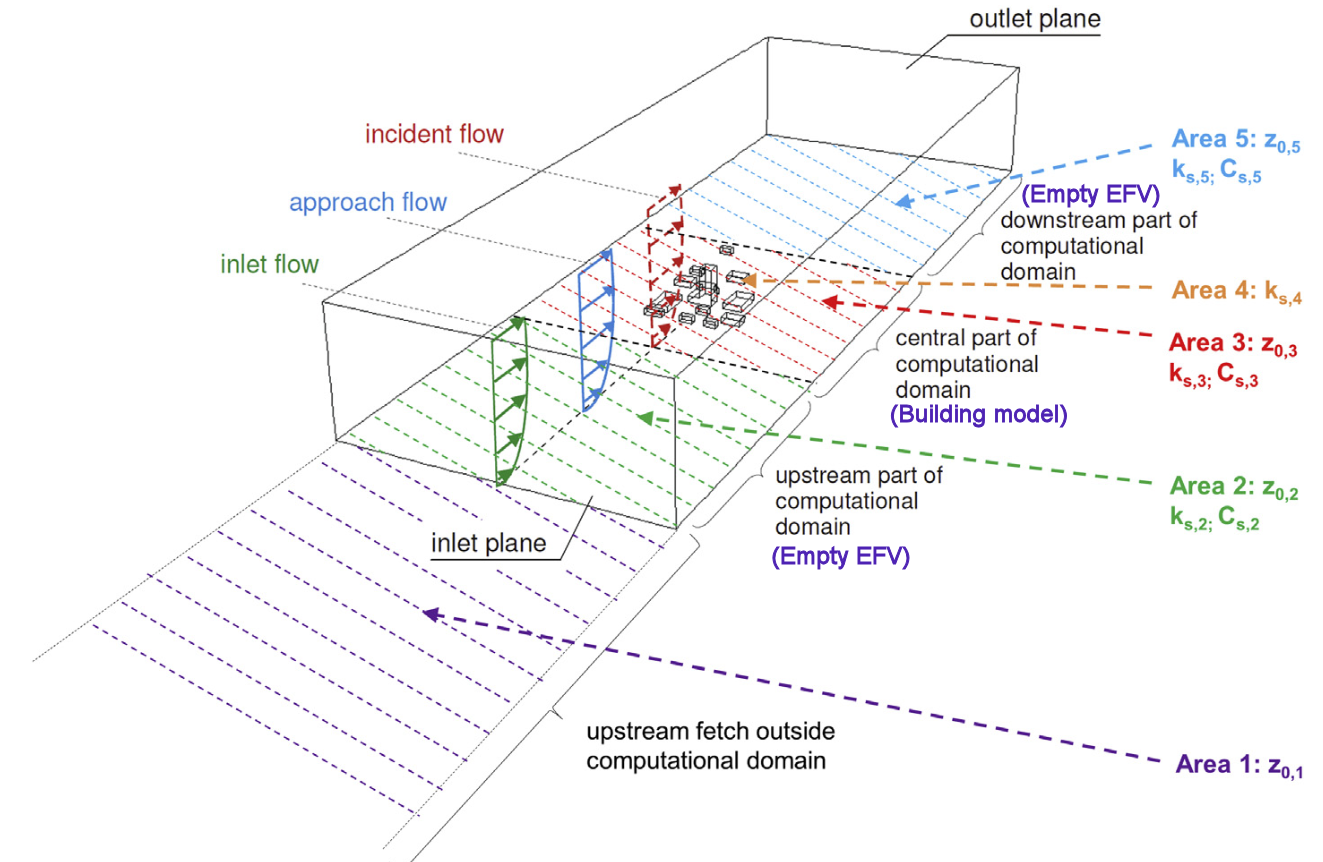

Some six different regions can be defined (between square

brackets, the location

and recommended grid size):

- Buidling model

- Functional spaces (e.g. the space for the rotating sails

[radius 15m and thickness 1m] or location of an anemometer

above the cap [4*4*4m]): [1 ->

0.3m]

- Mill (building of interest) (say radius 15m [sail length],

height 45m [mill cap height + sail length]): [2 -> 0.75m]

- Surrounding buildings (radius of 50m): [3 -> 1m]

- Influence circle (radius of 400m): lowest 10m has [4 ->1], rest [5 -> 2.5m]

- All regions have a height of mill cap height + sail length

- Empty External Flow Volume (EFV)

The Building model will be rotated (in model editing mode) to

simulate changing wind direction. If the CFD software supports PWC

[Pedestrian Wind Comfort), the rotation will be done within the

CFD machine.

CFD External Flow Volume (EFV)

There are two types of guidelines that need

to be obeyed when looking at the described wind mill environment

(EFV or windtunnel):

- Minimum distances (assumming the wind mill is in the

middle of the Influence circle) between the Building model

and the surfaces of the EFV (domain):

- Make sure that any building is at least 5*Hbuilding

from the lateral (Xmin and Ymin), inlet (Ymin)

surfaces of the EFV [Franke, 2007, page 18].

- Make sure that any building is at least 15*Hbuilding

from the outlet (Ymax) of the EFV [Franke, 2007, page

18].

- Ground: Zmin: height minimum = 0.05m (to overcome

model rounding errors [gaps]).

- Blocking ratio (Hmax is height of the highest

building; if Hmax is height of the mill cap height

then add the sail length to Hmax):

- Height EFV (Zmax): Hdomain>6*Hmax

[Franke, 2007, page 17]

- Blocking ratio: Adomain>3*Abuilding

[Gool, 2025, pers. comm & Blocken, 2015, formula 12]

Turbulence model

CFD solver must have minimum capability of solving the Navier-Stokes

fluid flow equations for a three-dimensional incompressible flow

analysis of steady state [Green Mark Department, 20016,

section A2].

RANS is being used and this provides a time-averaged stream. This

provides relative good results for wind velocities used for

turning/operating traditional wind mills (>2.5Bft).

Allowable turbulence models: one-equation Spalart-Allmaras model,

the standard k-ε model and its many modified versions, such

as the Renormalization Group (RNG) k-ε model and the realizable

k-ε model, the standard k-omega model and the k-omega

shear stress transport (SST) model [Blocken, 2015, page 229].

Recommendation: minimally standard k-ε model,

while RNG and realizable k-ε model provide good

solutions for an PWC (high Re number) environment (assuming that a

mill is a tall person;-) [Gool, 2025, pers. comm.] and [Franke,

2007, section B.2.1 for PWC].

URF’s [Under Relaxation Factor]: P=0.30, U=0.7, k=0.6, ω=0.6 (pers.

comm, Gool, 2025).

With k is:

k=((0.41*Uhref)/(ln((href+z0)/(z0))))^2/(0.09)^0.5 [m2/sec2]

with href normally 10m

With epsilon is:

epsilon=((0.41*Uhref)/ln((href+z0)/(z0)))^3/(0.41)/(z+z0) [1/sec]

with href normally 10m

LBM solvers would allow

a good time vayring solution of the wind mill environment.

No experience has been gained yet with this.

Atmosphere conditions

Temperature

Isothermal condition at 15°C air temperature [ISA 1976] at steady

state condition:

Kinematic viscosity:

1.50e-5 m2/sec

Density: 1.23

kg/m3

Atmospheric Boundary Layer [ABL]

The equations for the inlet ABL can be found at Blocken [2015,

section 5.4] (see also at SimScale).

A windspeed of 5m/sec@10m is taken.

Remember that the z0 can be different for different wind

directions (as it depends on the roughness of the wind [upstream

from the flow region] from that direction). The (average) wind speed

varies also with the wind direction.

Recommendation: use formula as given by SimScale.

It looks that OpenFOAM is not able to handle a high k (like 1.072),

so proposed to use 0.375 m2/sec2 [pers. comm.

van der Elst, 2025]..

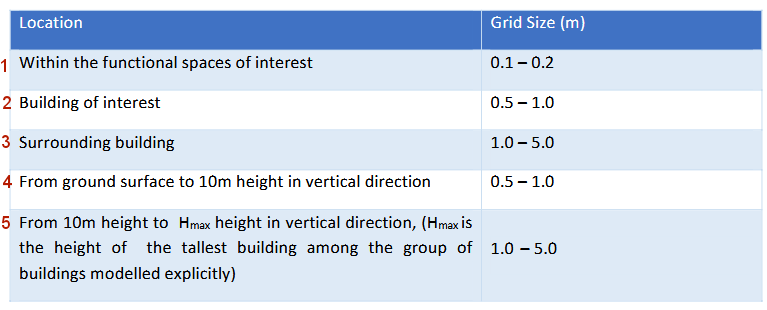

A quality mesh grid

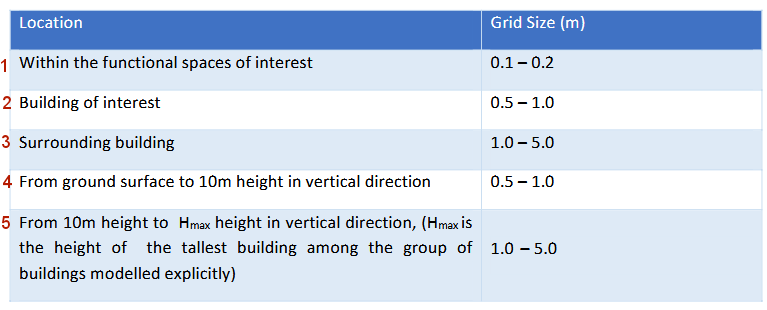

Using the earlier

described regions (without the functional space[s]), the

areas of different meshing sizes are depicted here:

Some recommendations by Green Mark Department [2017, section A5]

and Blocken [2015, page 232-233]:

- Recommended grid sizes:

- cell skewness <0.9

- Stretching ratio or Aspect Ratio <1.3

- Hexahedral cells are preferred (for instance Hex-dominant

setting in SimScale) over tetrahedral cells

- No tetrahedral cells at walls

- 10 cells per cube root of the building volume (minimum 3 cells

per direction)

- minumum 4 cells between every two buildings [2025, pers. comm.

Gool], otherwise merge the buildings [2025, pers. comm. Gool]

- A functional space or evaluation height should be at least in

3rd grid cell from ground.

- The mesh grid yg should be

larger than 2*ks

[SimScale and Blocken, 2007, section 6 and

7].

- create a gradual change in mesh sizes (to overcome volume

transition discountinuities; a volume transition of on average 4

or max. 5 [Wimshurst, 2022]);

which is a distance transition of average 1.6. This needs to

be matched also with the top layer of the boundary layer!

Others (e.g. SimScale ):

- make sure the mesh quality metrics

(Orthogonality<88; Edge Ratio<100; Volume Ratio<100;

Aspect Ratio<100; Tetrahedral Aspect Ratio [preferable]=0;

Skewness<100) are within boundaries

A grid

convergence study is recommended if no previous experience

has been gained.

<In the future an example of a bad

and good mesh will be presented on this page>

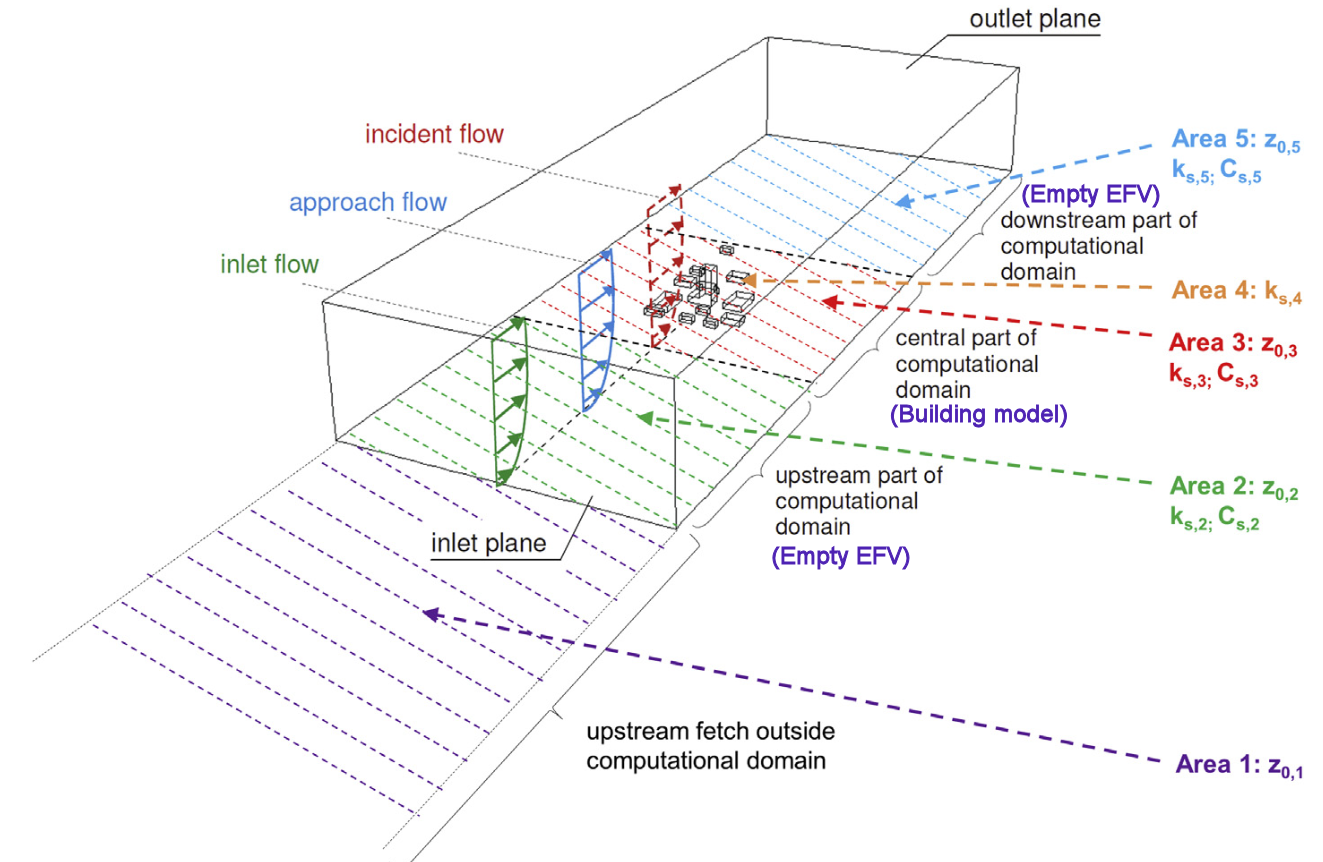

The roughness parameters

There are two types of roughness specifications:

- aerodynamic roughness length z0

This is used e.g. in the

ABL.

- equivalent sand-grain roughness height ks

ks is modelling height roughness for surfaces (in SimScale for ground

(non-slip wall))

There is the Roughness constant (Cs) (between

uniform (0.5) and strongly non-uniform (1) roughness height). A

common value for Cs looks to be 0.9 as quoted from

Blocken by Townsend [2024, page 2], but other values are

possible [Townsend, section 3].

For software based on OpenFOAM (such as

SimScale) and ANSYS/Fluent, the conversion between z0,

ks and Cs is:

ks~9.8*z0/Cs and using Cs=0.9

gives ks~10.9*z0

For ANSYS-CFX based software, the conversion between z0

and ks is:

ks=29.6*z0 (as it has an implicit/fixed Cs=0.33)

The mesh grid size yg should be

around ks (yg>2*ks and yg=2*yp).

A mesh grid size of yg of 1 to 5m (Surrounding buildings)

looks to be minimumly needed, and that would result in a ks

of 0.67m to 3.33m or a z0 of around 0.07m to 0.33m.

Thus a roughness height modelling could be done for an Open

(z0 = 0.03m) to Rough environment (z0

= 0.25m), all other environments with a higher roughness

length z0 should be modelled using explicit 3D boxes

[Blocken, 2007, section 7.1(b)].

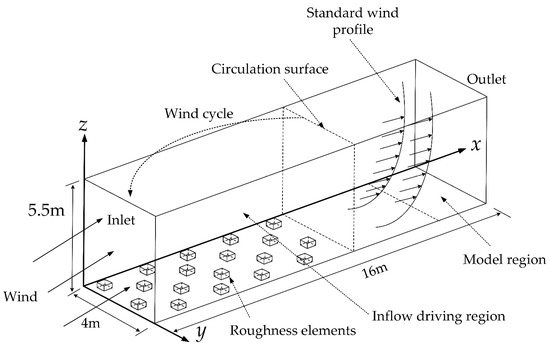

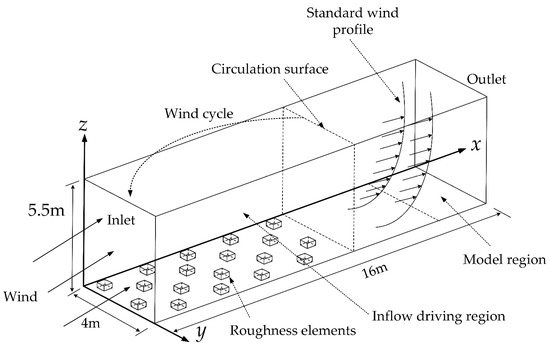

An example how this is done can be seen in this picture [Chen,

2022, Figure 1]:

Different roughness araes

Figure 16 of Blocken [2015].

In SimScale:

- Area 1: impleciet by ABL

- Area 2, 3, 4 and 5: governed by roughness height (ks-x)

and roughness constant (Cs). See for relation between

z0, ks and Cs here. Best values

for ks; if

z0 is not too large:

- ks,2: related to inlet z0

- ks,3: related to inlet z0: ks,3=ks,2

- ks,4: related to an z0 < 0.1m, or

let say ks,4<ks,2/10. This ks,4

can be small as the modelled obstacles will determine the real

roughness.

- ks,5: related to inlet z0: ks,5=ks,2

Also check that the stream is reacting properly to changing ks.

Remark: Still need to find out how to

make several areas of different Roughness height ks

and Cs for the EFV in SimScale. This needs to be done in the CAD program:

SketchUp is not able to do this: Better to use OnShape. For

now: for all areas 2, 3, 4 and 5 the same (z0,) ks-x

and Cs are used.

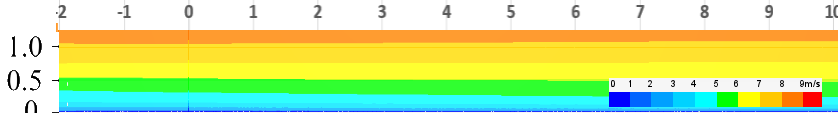

Horizontal homogeneity of empty

computational domain

When one removes all objects (but keep roughness heights/lengths

as wanted), a horizontal homogeneity in speed and turbulent

kinetic energy should be achieved.

Is horizontal homogeneity also needed for

turbulent kinetic energy?

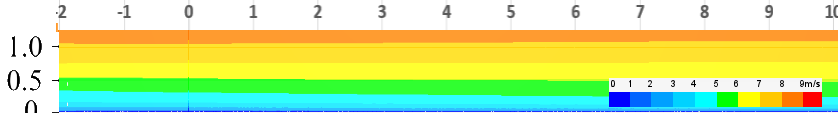

And example is here (-13.6m to 68m):

Also check that the stream is reacting properly to changing ks.

Higher-order discretization schemes

Don't use 1st order gradient schemes; 2nd

order (such as Gauss) should be ok.

SimScale uses default

Gaussian integration.

Evaluation of convergence

Check in the convergence plots if the solution converges smoothly

and converges to a stable end (so no oscillations). Termination

threshold (for for instance pressure) preferrable around 10-3.

Recommendation: Check in SimScale: Simulation Runs ->

Convergence plot -> Residuals

Grid convergence study

The mesh grid resolution should be varied using

a linear refinement factor of at least 1.26 in each direction (so

that is around 2 [~1.263] for 3 directions). The

results should not change significantly. At least three

refinements checks need to be done (reduce and increase the recommended grid

sizes with factor of 1.26).

What do we measure

Wind speed (perpendicular to the plane of the sails: at eight

locations [long and short rest positions] at 3/4 of the sail

length), the turbulence intensity (TI), y+ (according to SimScale; but I have not seen

practical use for it in wind mill environment. If people have

ideas, let me know) and convergence plots.

Validating the results

One needs to validate the results using scientific articles.

Areas to be covered:

- study of non-CFD methodologies

Examples: DHM-formula,

ST workflow,

EJL workflow

- porous media to proxy trees: comparing CFD results with

published measurements in vivo

Examples: Nageli,

Ren, Tree proxies

- comparing CFD results with professionally made wind quality

reports around traditional wind mills (that use CFD or other

methodologies).

Examples: De

Hoop, Rijn en Lek

- comparing CFD with wind measurements at traditional wind

mills.

Examples: Impington,

Rijn en

Lek

- consult CFD experts.

See acknowledgements section on each web page

- keep critically reviewing the meshing sizing and CFD results.

Example: CFD tips,

open questions

Conclusions

If one compares two or more environments, the relative valuee become

important. If the aerodynamic system is relatively linear, all

unknown method parameters will be divided out, and thus the values

of these parameters become a little less important (again: as

long as we are in a linear environment)!

<Can only provide text for this section when things are fully

understood, reviewed and tried>

References

Blocken, Bert et al.: Modification of

pedestrian wind comfort in the Silvertop Tower passages by an

automatic control system. In: Journal of Wind Engineering

and Industrial Aerodynamics 92 (2004), pp. 849-873.

Blocken, Bert et al.: CFD simulation of the

atmospheric boundary layer:wall function problems. In:

Atmospheric Environment 41 (2007), issue 3, pp. 238-252.

Blocken, Bert: Computational Fluid

Dynamics for urban physics: Importance, scales, possibilities,

limitations and ten tips and tricks towards accurate and

reliable simulations. In: Building and Environment 91

(2015), pp. 219-245.

Chen, Zhaoqing et al.: Numerical simulation of Atmospheric

Boundary Layer turbulence in a wind tunnel based on a hybrid

method. In: Atmosphere 13 (2022), issue 12.

Franke, Jörg et al. COST Action 732: Best

practice guideline for the CFD simulation of flows in the urban

environment. Brussels, COST Office 2007.

Green Mark Department: BCA GREEN MARK FOR

RESIDENTIAL BUILDINGS: Technical guide and requirements. In:

(2017), issue GM RB: 2016.

Townsend, Jamie, F. et al.: Roughness constant

selection for atmospheric boundary layer simulations using a k-ω

SST turbulence model within a commercial CFD solver. In:

Advances in Wind Engineering 100005 (2024), pp. 1-10.

Winshurst, Aidan: Sizing inflation layers

using a y+ estimation tool. In: (2022).

Winshurst, Aidan: Fluid mechanics 101:

Calculators & tools. In: (2025).

Acknowledgements

I would like to thank people, such as Frank van Gool, Ezra van

de Elst, SimScale Support and others for their help,

encouragement and/or constructive feedback. Any remaining errors

in methodology or results are my responsibility of course!!! If

you want to provide constructive feedback, please let me know.

Major content related

changes: January 8, 2025